Automation

Efficient automation: linking manufacturing steps for seamless process control

Composites – Automation

Automation by combining or linking of single or multiple production steps up to integration and control of complete process chains.

Tapelayer & Laying Systems

Composites – Automation

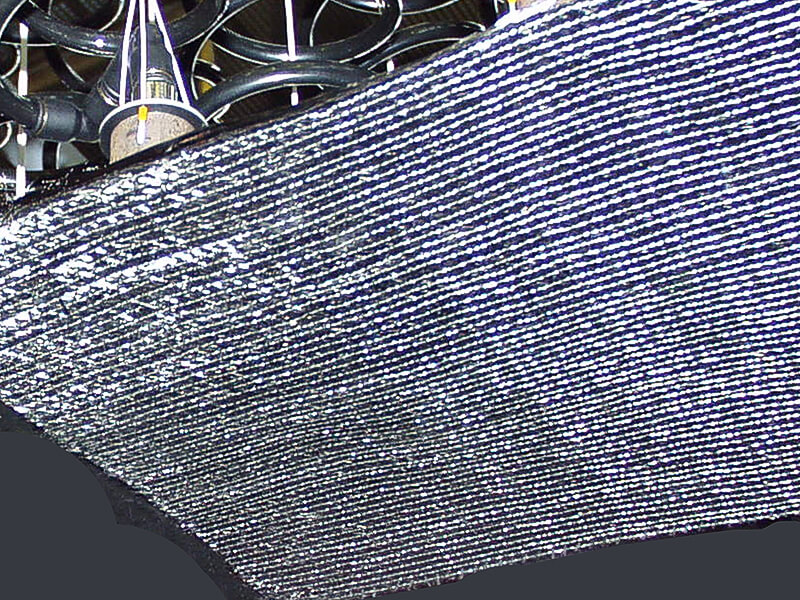

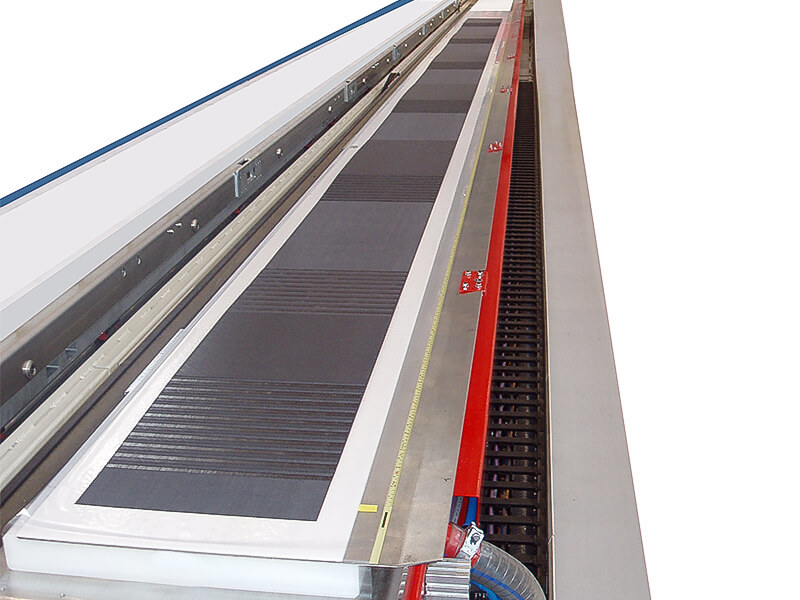

Laying and Ultrasonic Cutting

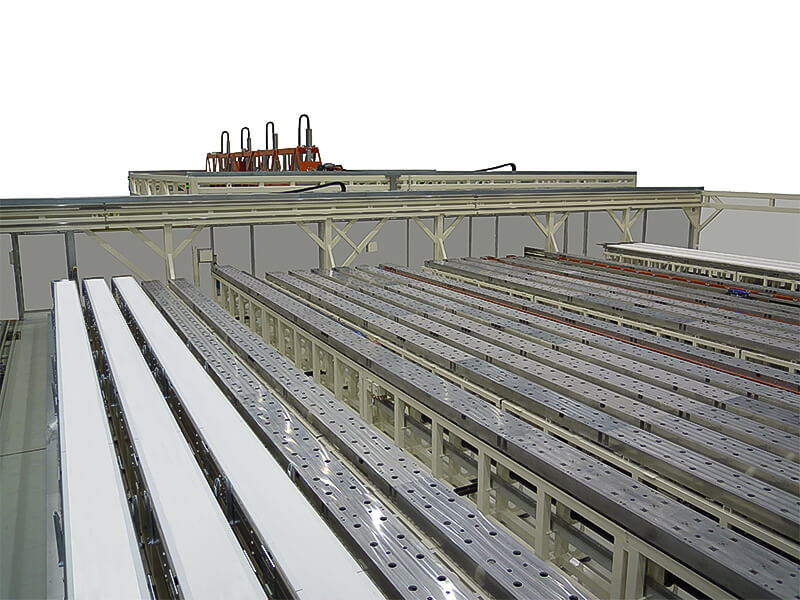

GFM has specialized in the production of Tapelayers for flat layups. The laying process is performed on a vacuum table with a cutting surface on top. Right after the laying process the layups are cut to the desired shapes by Ultrasonic Cutting. For mass production as well as for producing special layups we can supply systems with multiple laying heads or laying cassettes. For laying of dry materials the laying systems are adapted accordingly.

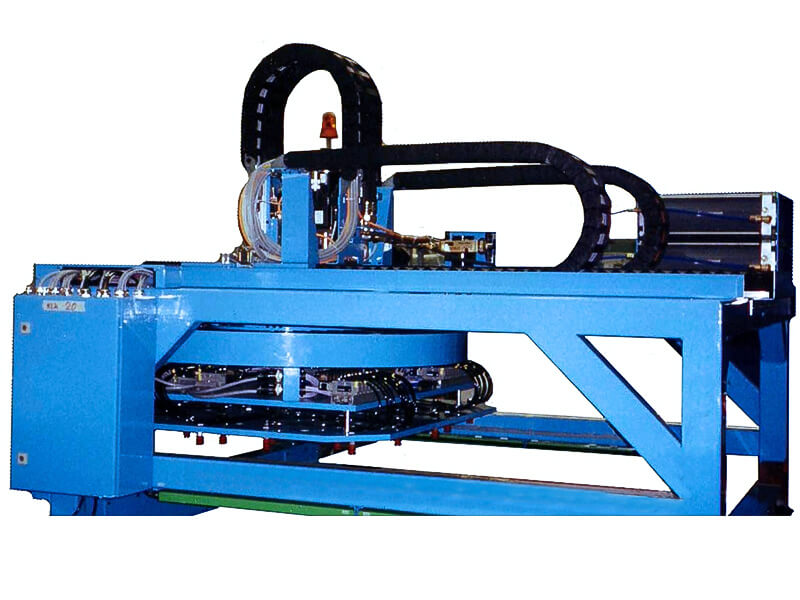

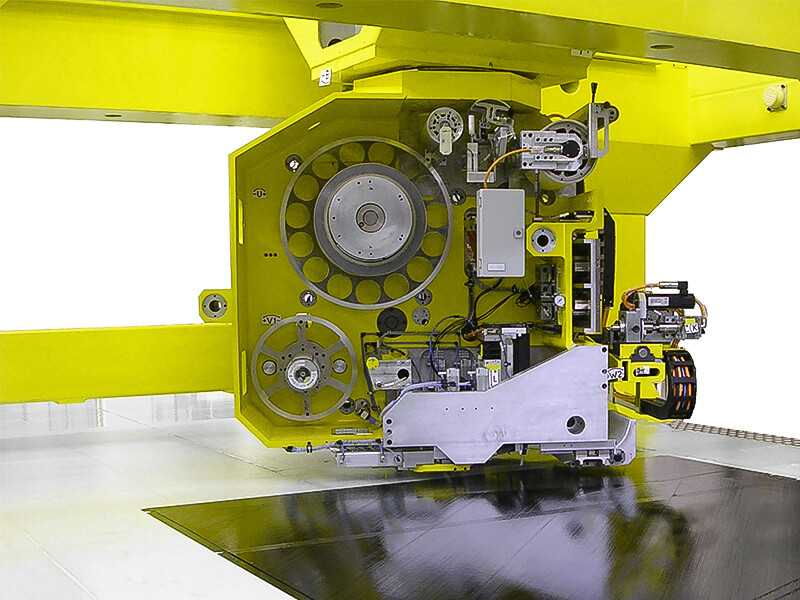

TL-30

Tapelayer for flat layups

- Tape layers for level lay-ups with 75-150-300-mm-wide tapes

- Combination of laying and cutting table

- Ultrasonic cutting system for layup cutting

- No special foundation necessary

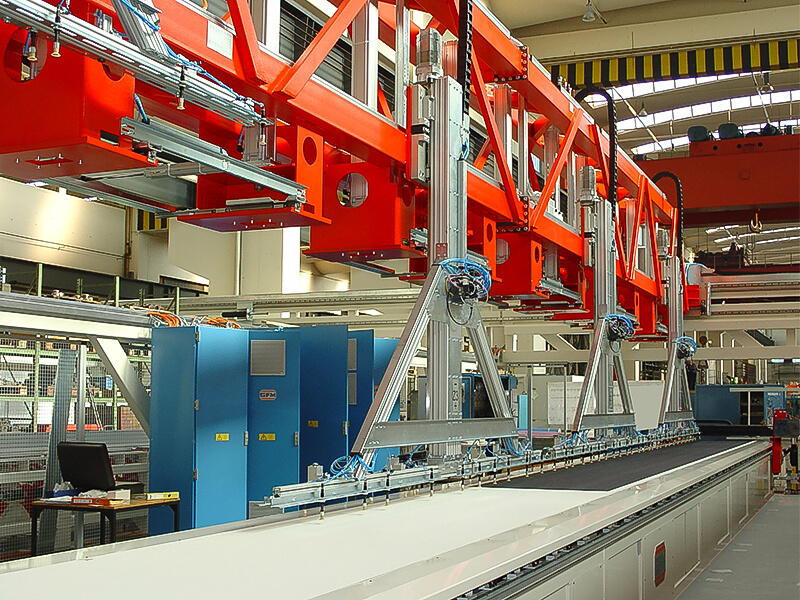

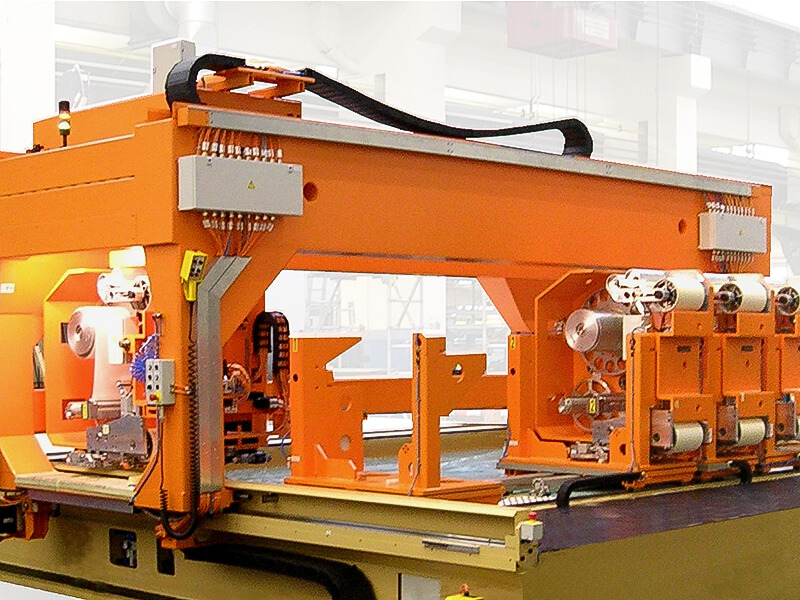

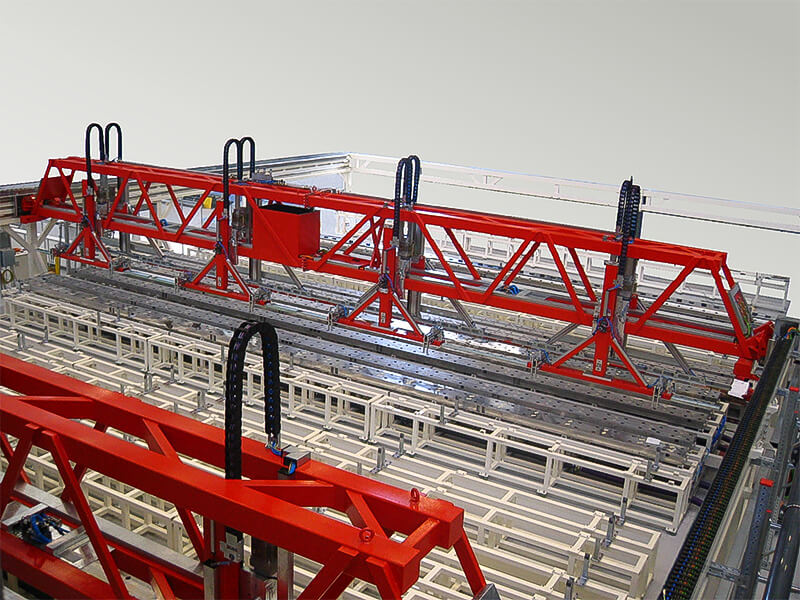

TL-20 – Multihead Laying System

Laying system for long layups with multiple laying heads

- Lays different materials

- Layups also with different material widths

- System for mass production

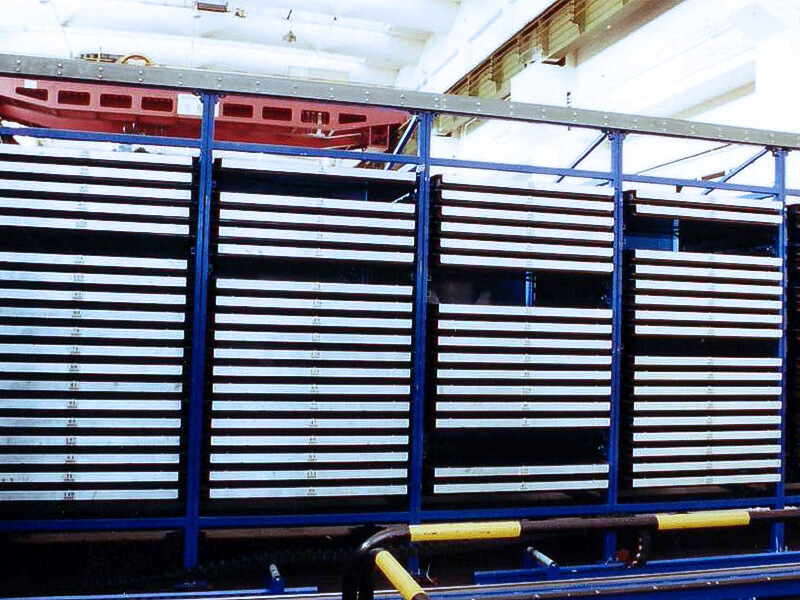

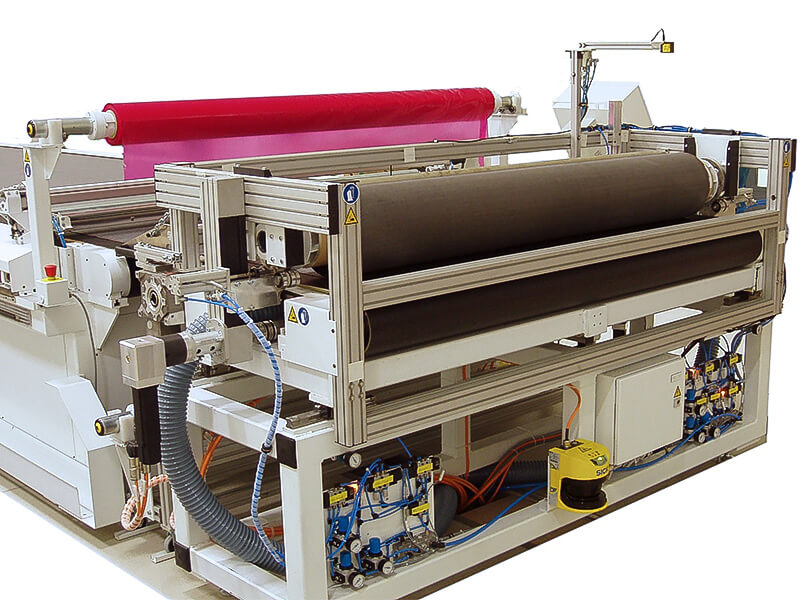

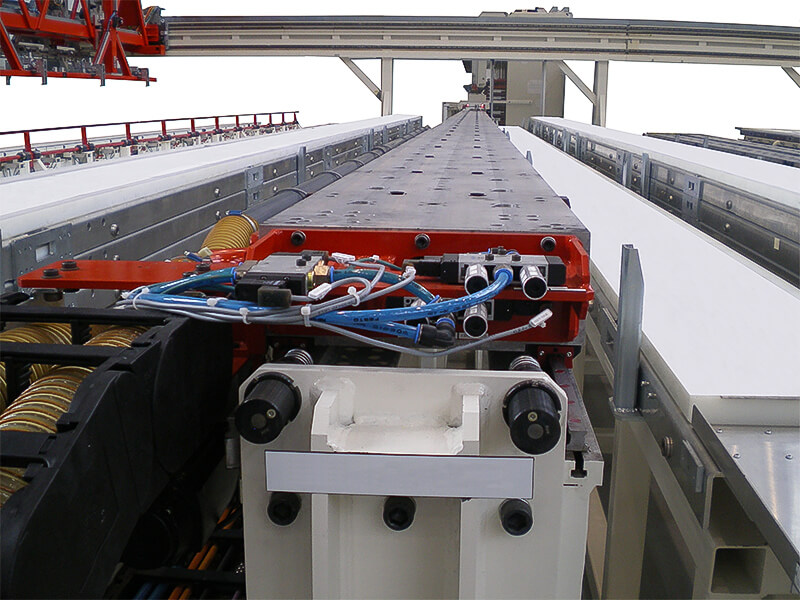

TL-30 Cassette Laying System

For a mix of materials in flat layups

- Tape layers for level lay-ups with 75-150-300-mm-wide tapes

- Combination of laying and cutting table

- Lays different materials depending on the number of cassettes

- Ultrasonic cutting system for layup cutting

- No special foundation necessary

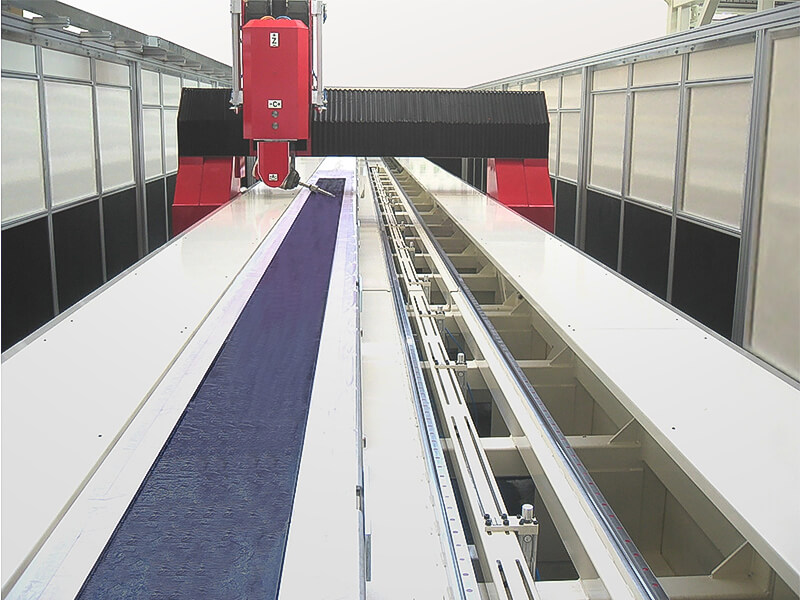

Customized Laying Systems

For specific tasks

- Various prepregs

- Dry goods – Multiaxial layups

- The configuration is engineered to meet the specific process requirements

Automated Production Cells

Composites – Automation

Of Process Chains

Subsequent production steps are increasingly automated by integrated composite production cells to meet the rising demands to productivity and quality.

Production Cells

Complete Systems

Everything from a single source – based on following GFM Technologies:

- Laying

- Forming

- 2D and 3D Cutting

- Pick&Place

- Pre-assembly

- The cells are supplied with Handling Systems developed by GFM

- Including Programming Systems, Control- and Administration Software

The optimal cell configuration is defined in close cooperation between our customers and the GFM specialists.

For detailed information please look at our Whitepaper.

Pick-Place-Distribute

Composites – Automation

Cutting and Automated Unloading

The increasing productivity of our Ultrasonic Cutting Machines opens the opportunity of economic Automation of the subsequent production steps Unloading, Sorting and Laminating, especially in the mass production of composite parts.

Pick – Place – Distribute

From cutting to manual or automated lamination

Everything from a single source:

- GFM Ultrasonic Cutting Machines with Unwind System and Unloading Area

- Smart GFM Gripping Systems

- GFM Transfer Systems or Robot

- GFM Cut/Ply Storage Systems

- GFM Draping Systems – Automated Draping for mass production

- GFM Cell Controller for optimized process flow, Nesting, Sorting and Administration

Photogallery