Cutting / Profiling

Ultrasonic Cutting Machines – unsurpassed cutting quality for every requirement

Ultrasonic Cutting Machines

The incomparable high cutting quality of the GFM Ultrasonic Cutting Technology is achieved with all GFM Ultrasonic Cutting Machines. There is a wide range of machine types and configurations for many different tasks.

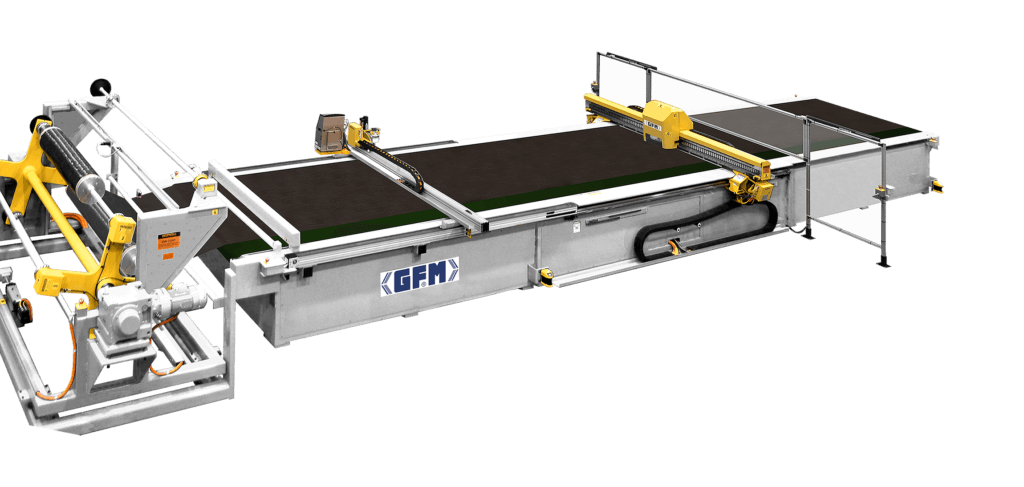

2D Cutting

2D Ultrasonic Cutting Machines

Highest Cutting Quality

No matter how diverse cutting tasks may be – Our solutions match them.

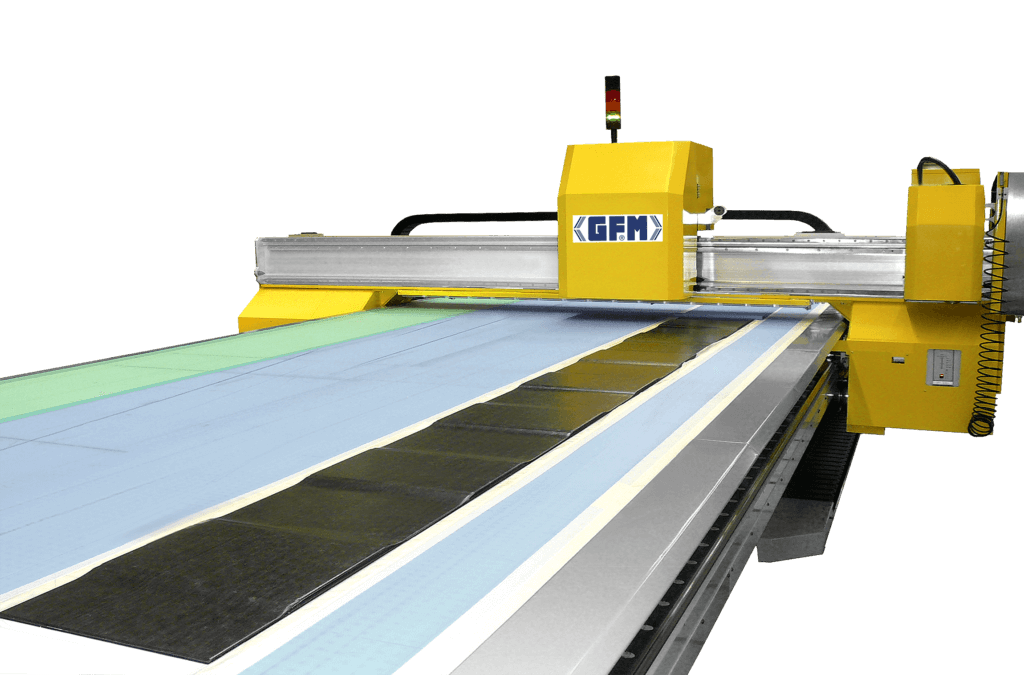

CM-10

Conveyorized single layer cutter

Window cutting technology for large plies and nests. Cuts a broad variety of materials. Unloading of plies in separate unloading area is either manually or by Pick & Place System.

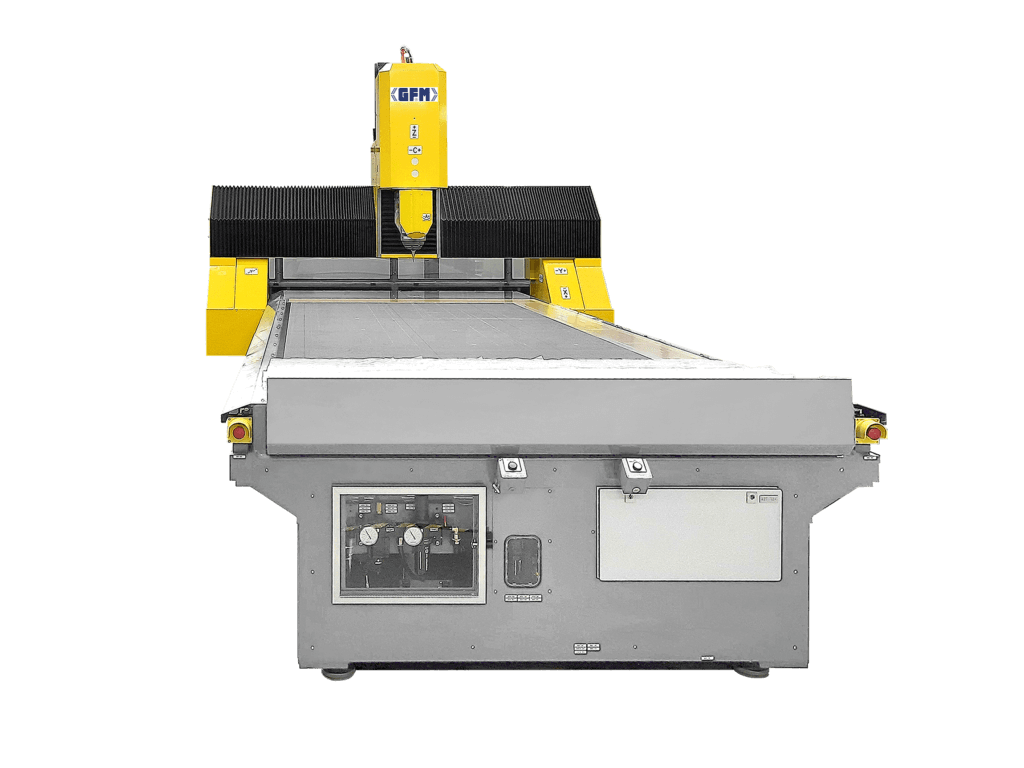

US-20

Single and multiple layer cutter

- With static cutting area – optionally with air floatation

- Conveyorized – optionally with loading and unloading area

- Unwind Systems for sensitive materials or heavy rolls

- Many configuration options

US-120

The fastest and most precise cutter

- With static cutting area – optionally with air floatation

- Conveyorized – optionally with loading and unloading area

- Linear motors and extremely sturdy structure ensure extraordinary results

- Many configuration options – also Multi-Head versions

US-30

High Precision Cutter for heavy cuts

- With static cutting area – optionally with air floatation

- Conveyorized – optionally with loading and unloading area

- Many configuration options

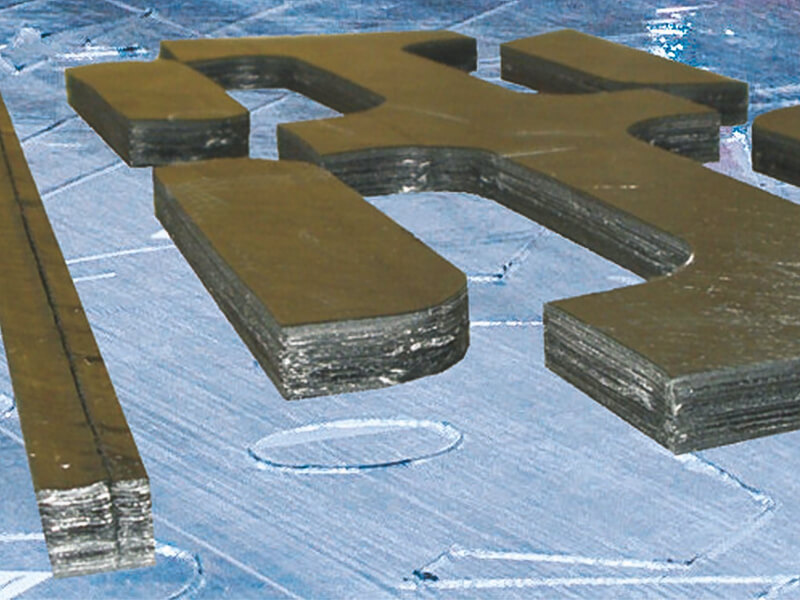

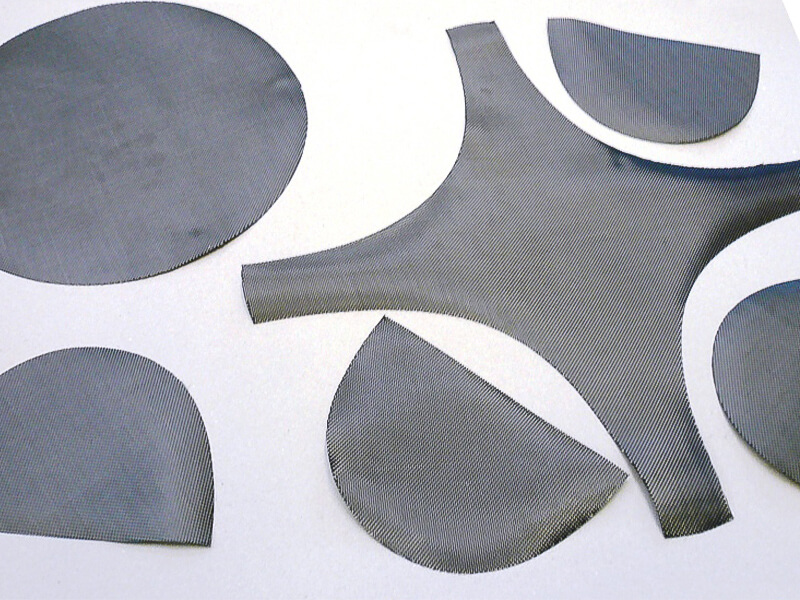

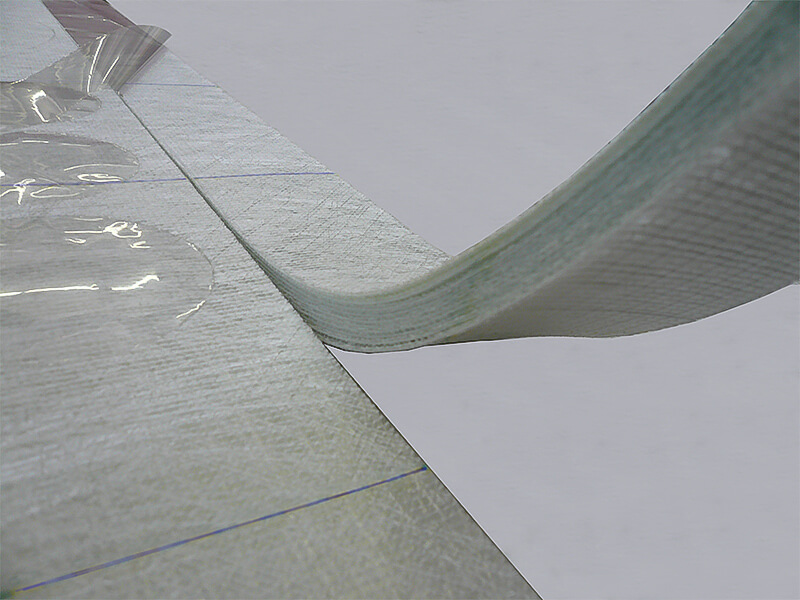

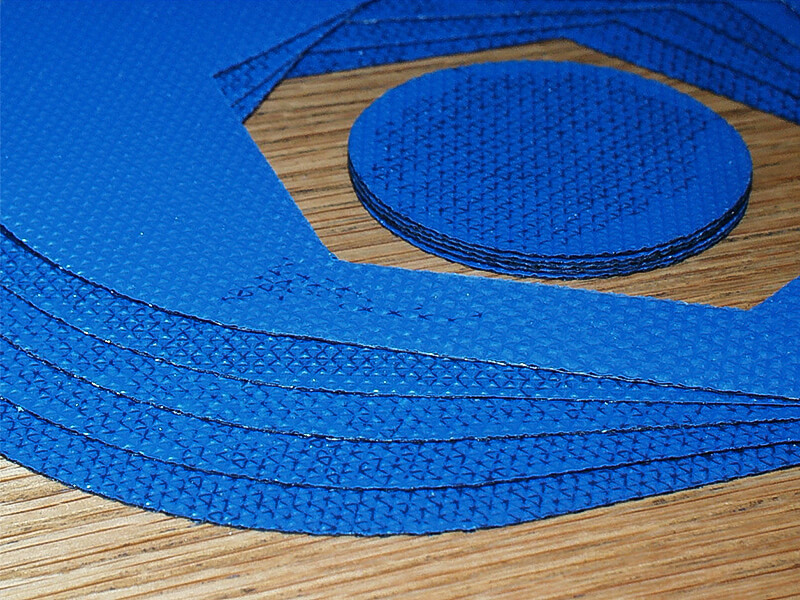

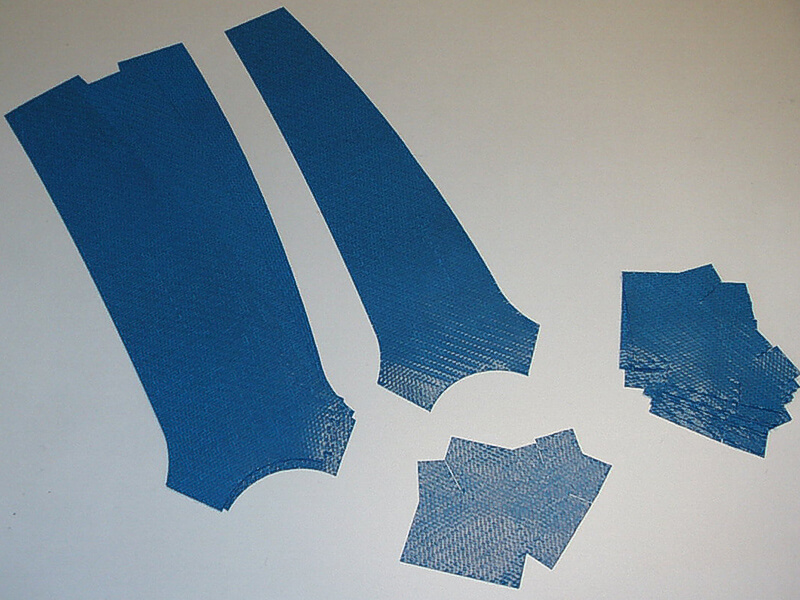

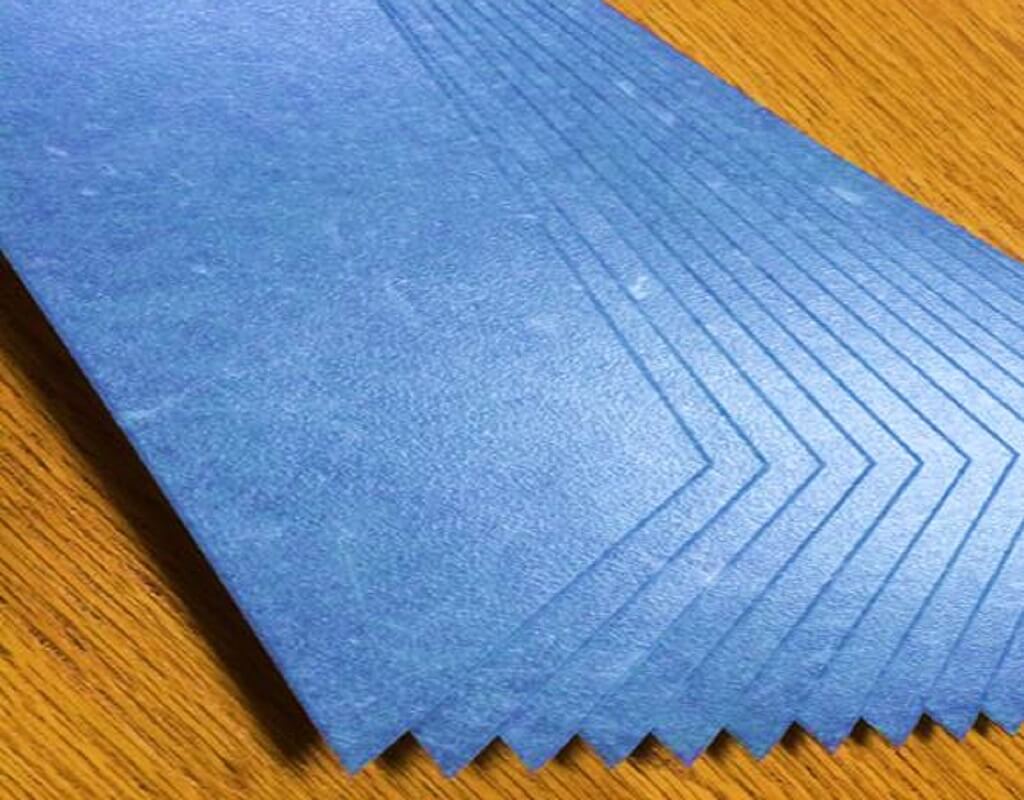

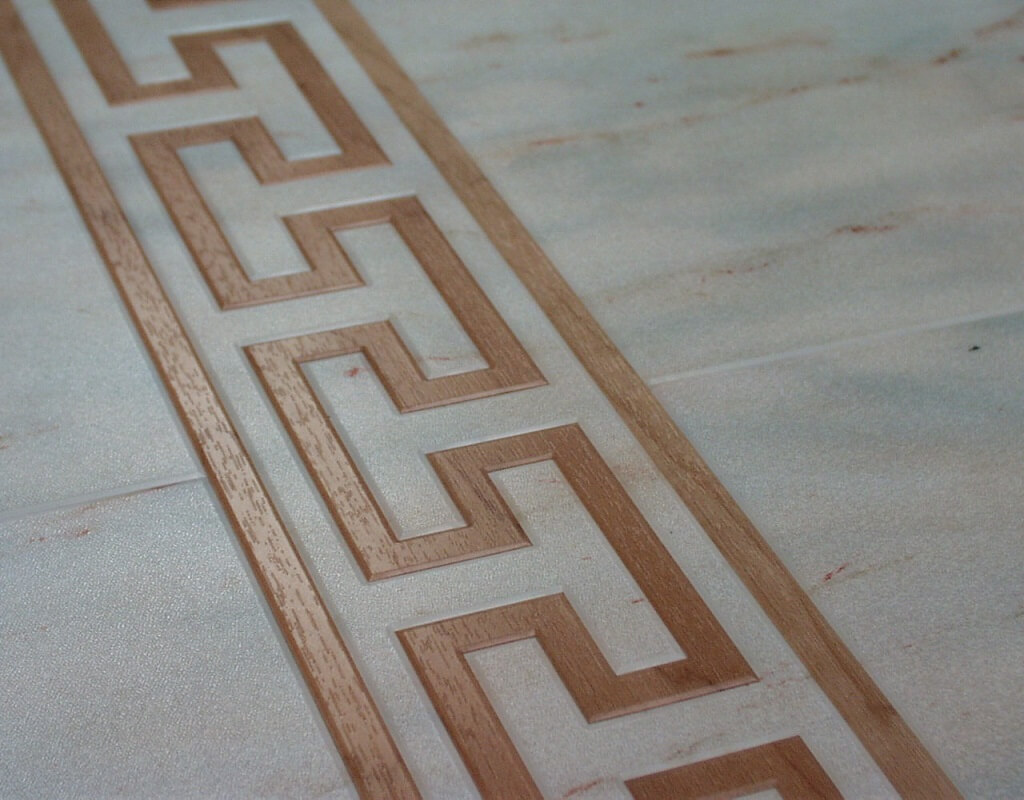

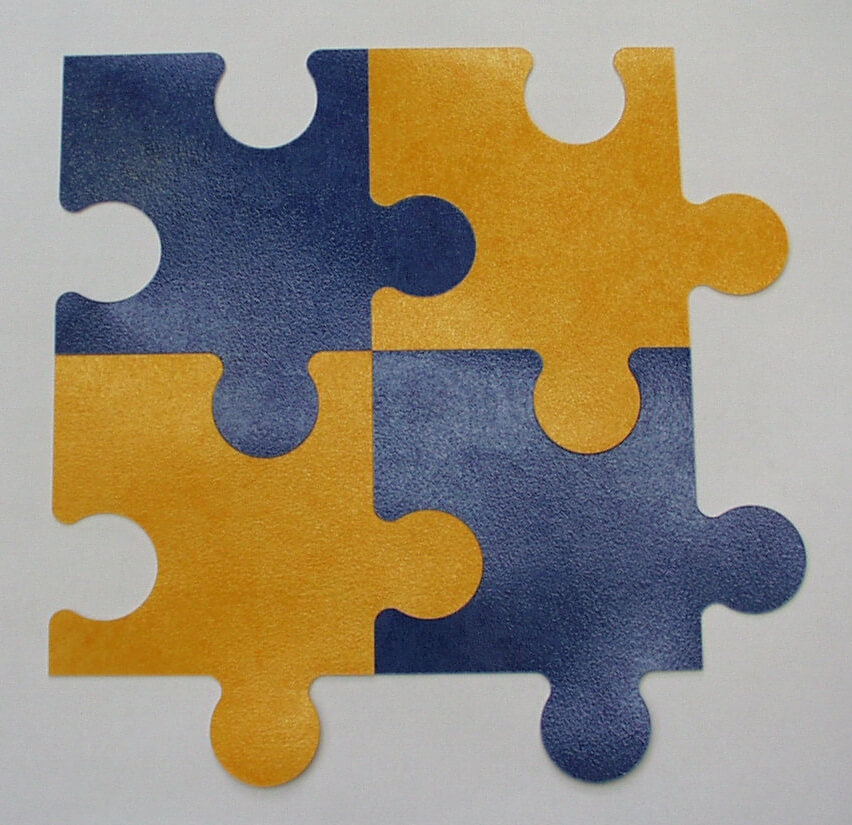

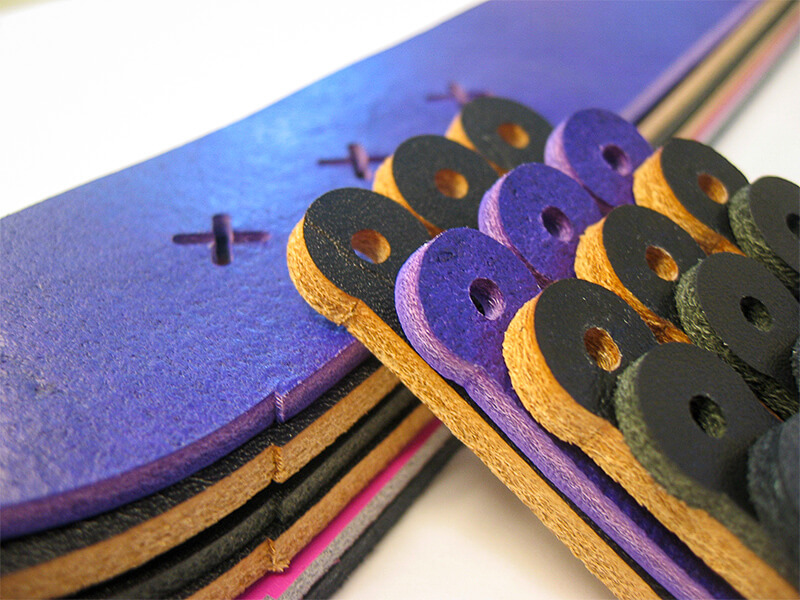

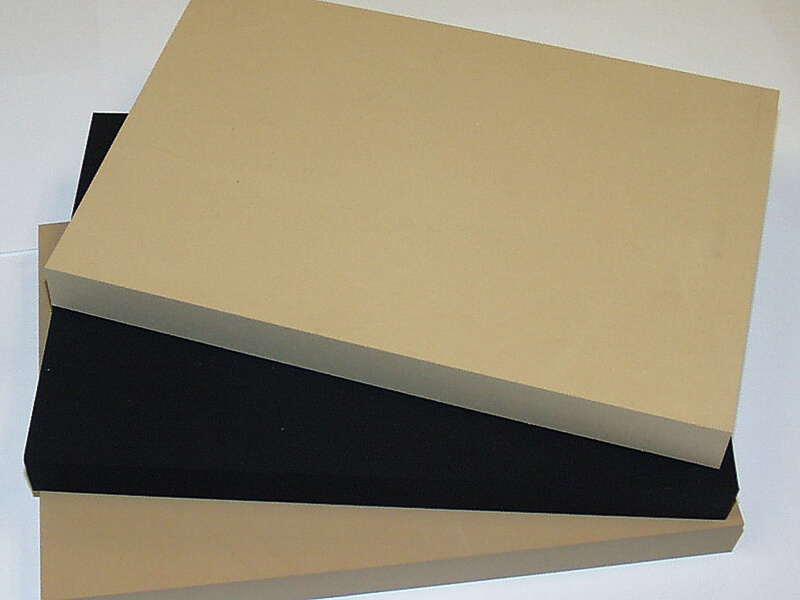

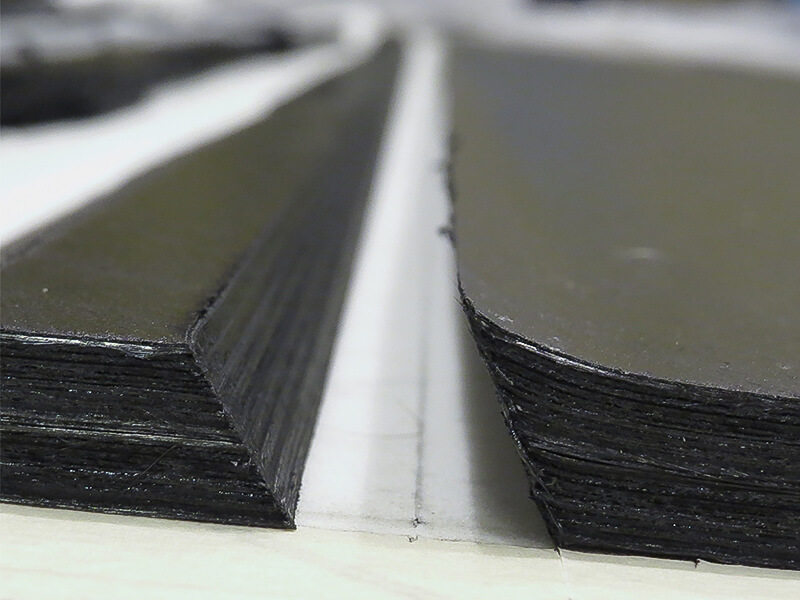

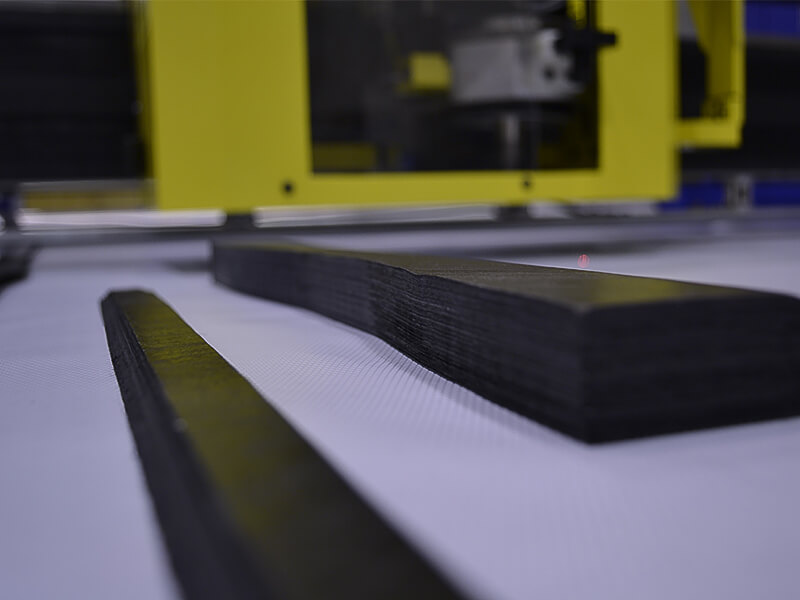

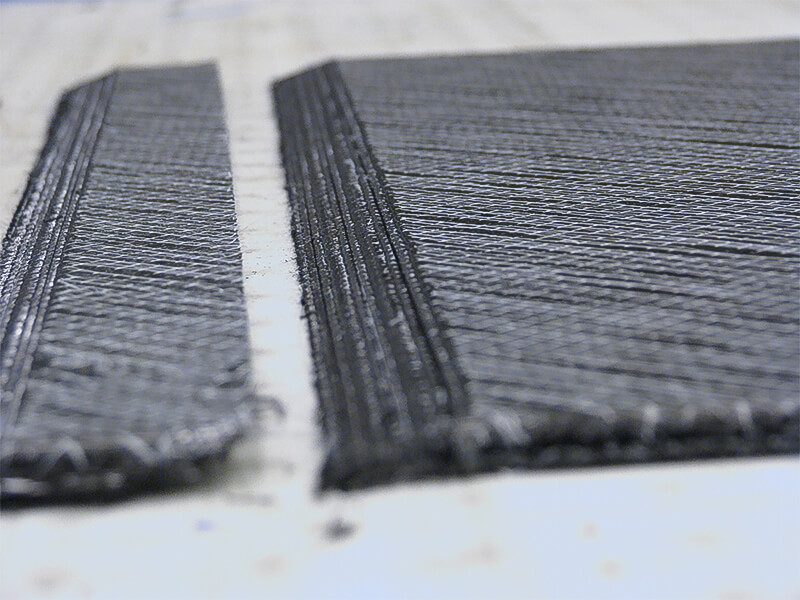

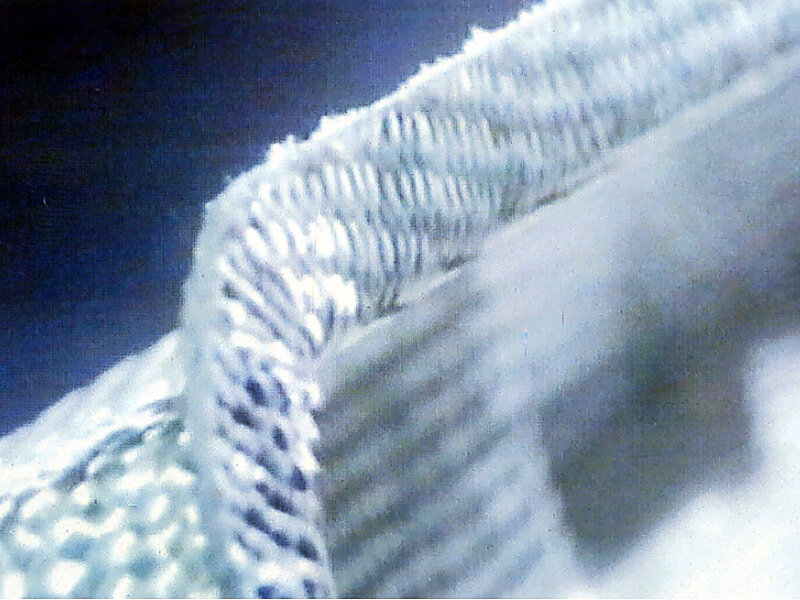

2D Cutting Samples

Highest Cutting Quality

The GFM ultrasonic cutting method cuts many different materials. Here are some examples:

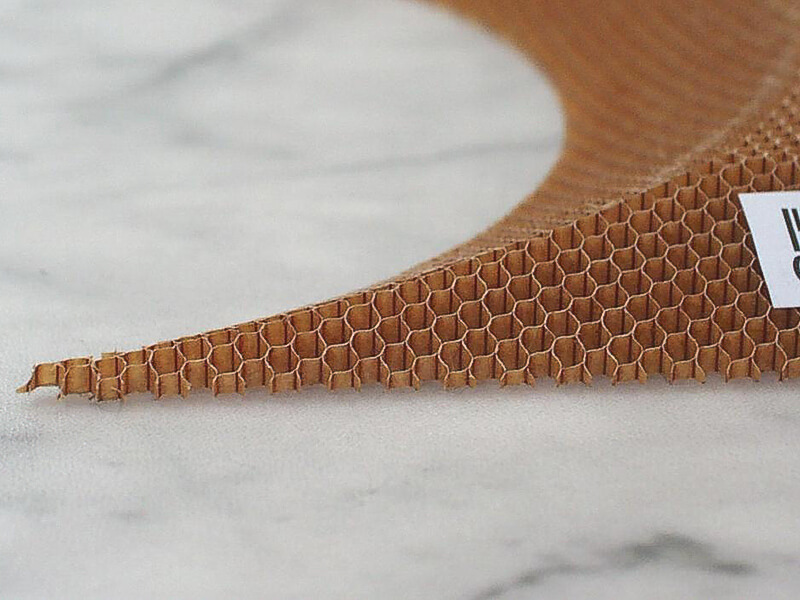

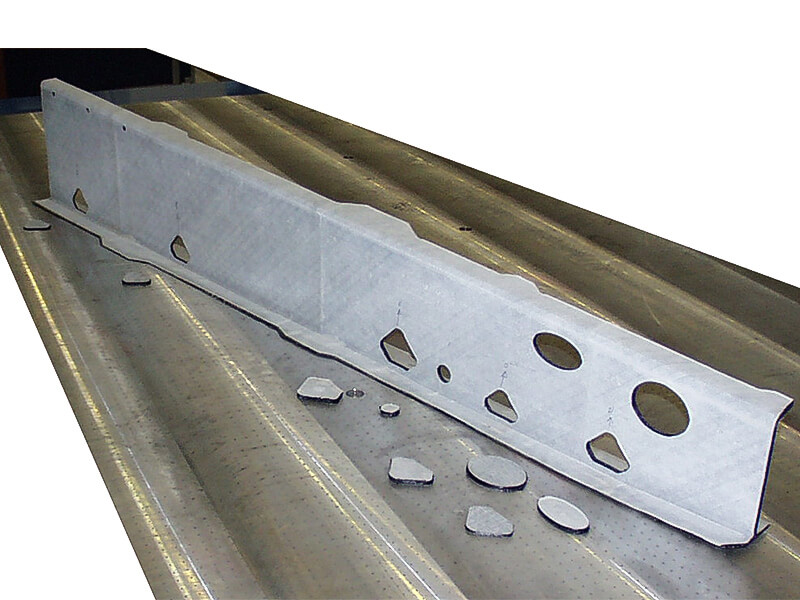

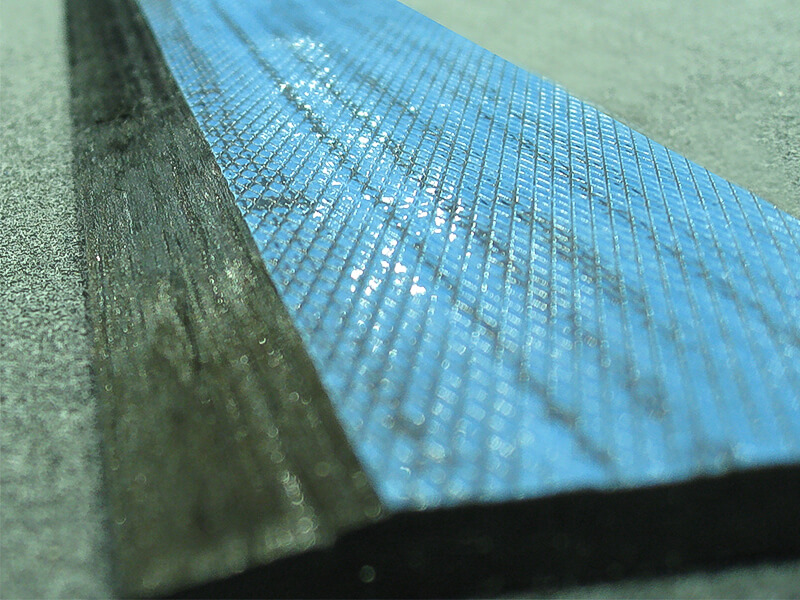

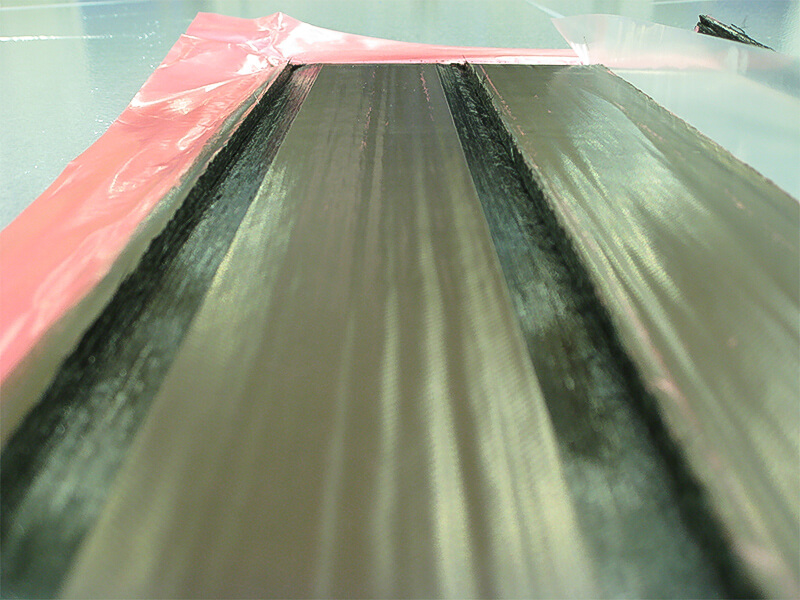

Composites

Floorings

…and many other materials

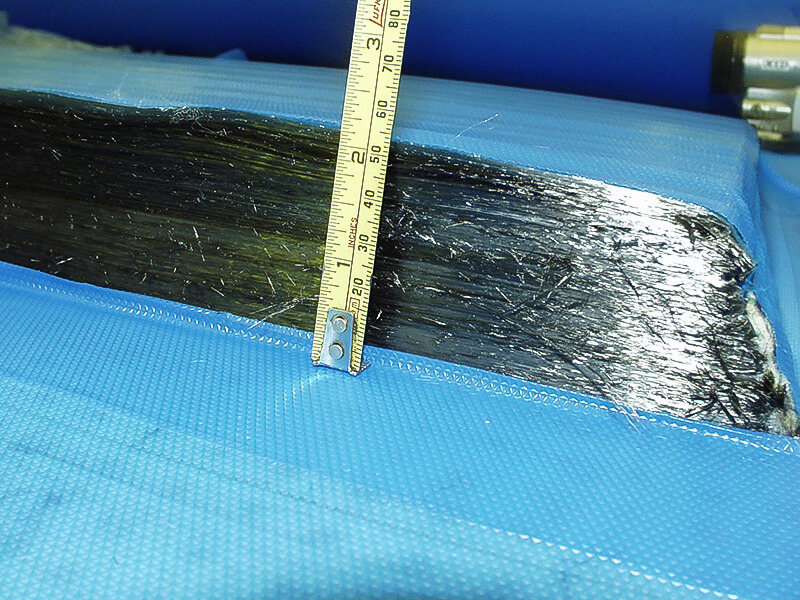

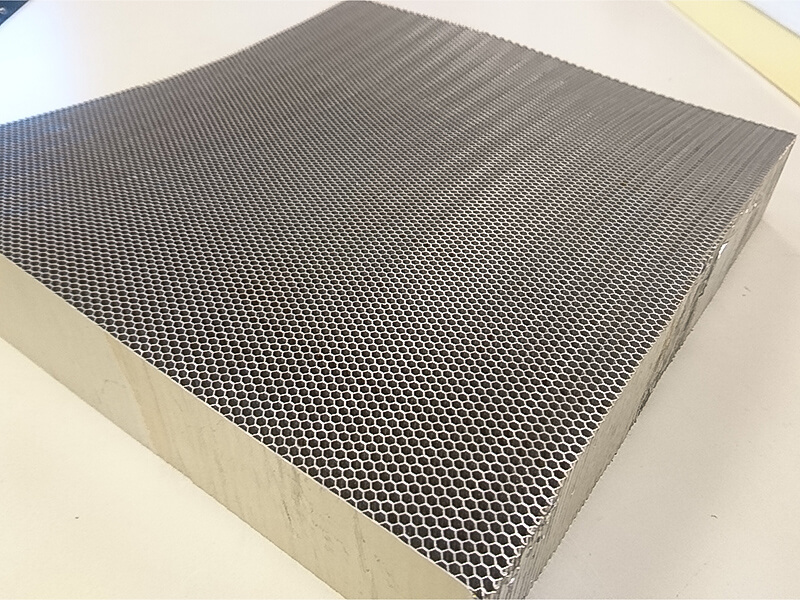

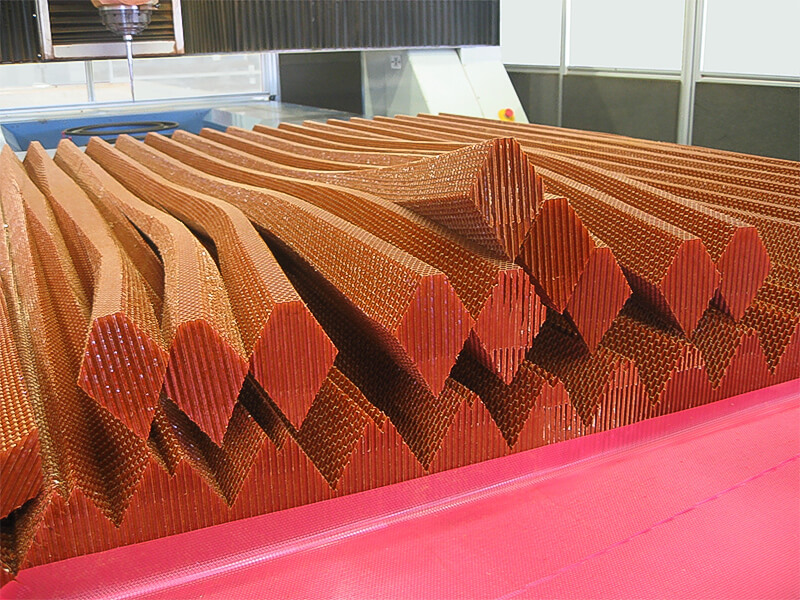

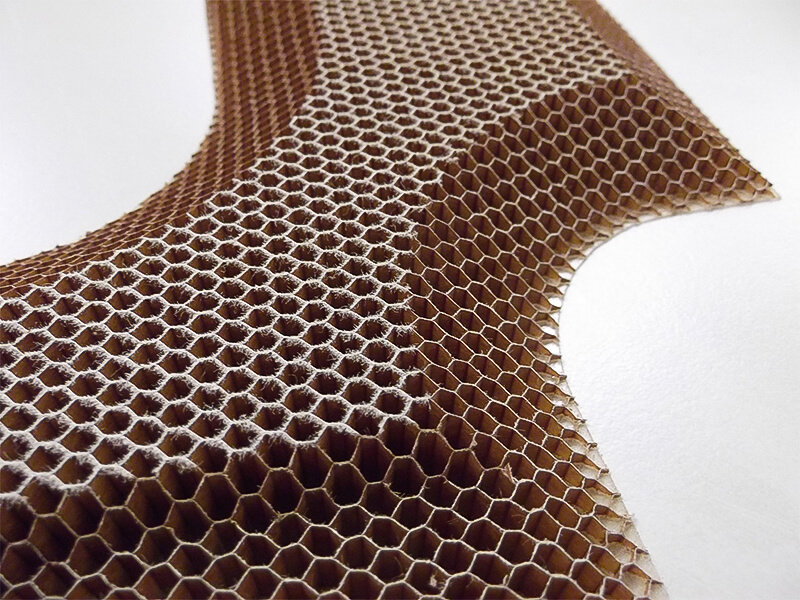

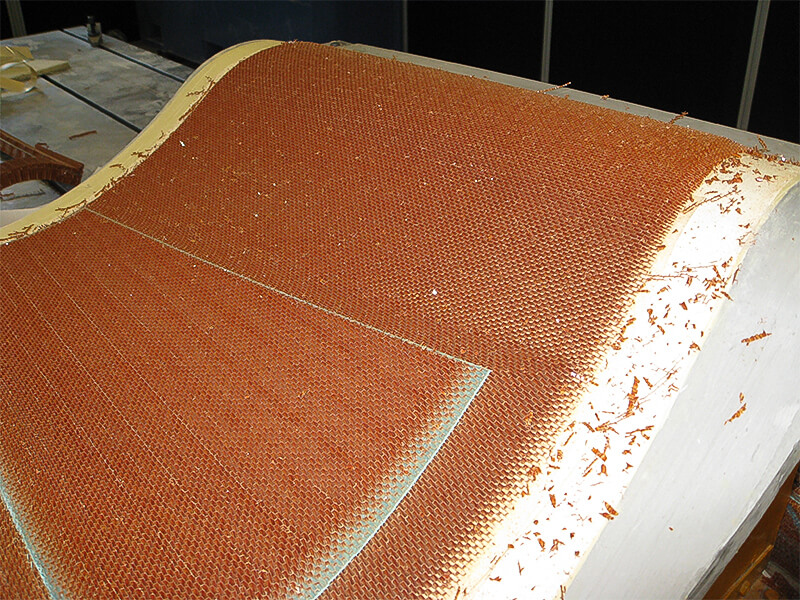

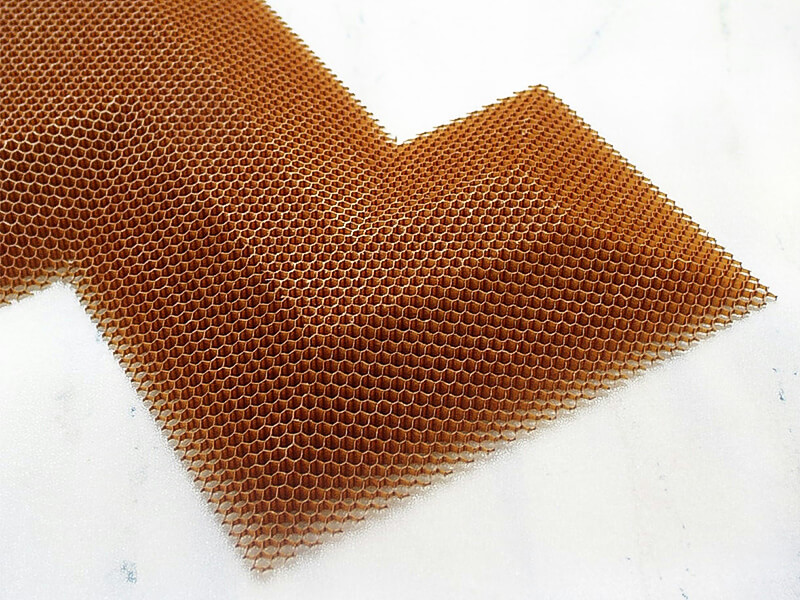

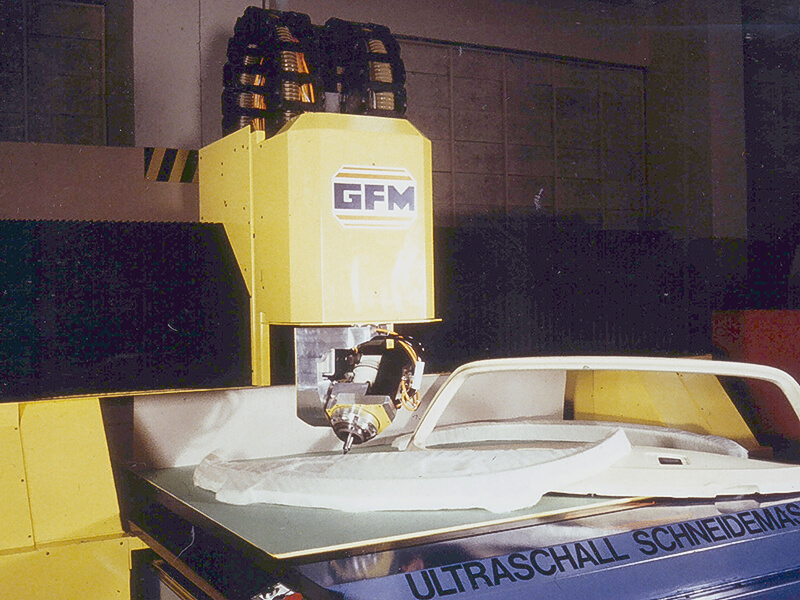

3D Ultrasonic Cutting Machines

Honeycomb processing can be simple

Since more than 25 years, GFM Machines are cutting honeycomb materials with highest quality by utilizing the GFM Ultrasonic Cutting Technology. Our customers are always one step ahead due to the continuous development at GFM. GFM application engineers support you also in the implementation of complex tasks.

GFM Ultrasonic Cutting Machines ensure also best results on 3D cutting of carbon fiber layups and preforms.

US-50

3D Cutter for honeycomb materials, carbon fiber layups and preforms

- Simple fixation of honeycomb panels by vacuum

- Intelligent Fixtures for complex shapes

- Single- and double-sided machining of honeycomb part

- Optimized programming tools for NC part programming

USR-60

Combination of 3D Ultrasonic Cutter and Router

- Two full fledged technologies on one machine

- Highest processing quality in honeycomb and hard materials

- Task-specific configuration

- Also available as 3D Ultrasonic Cutter or as Router

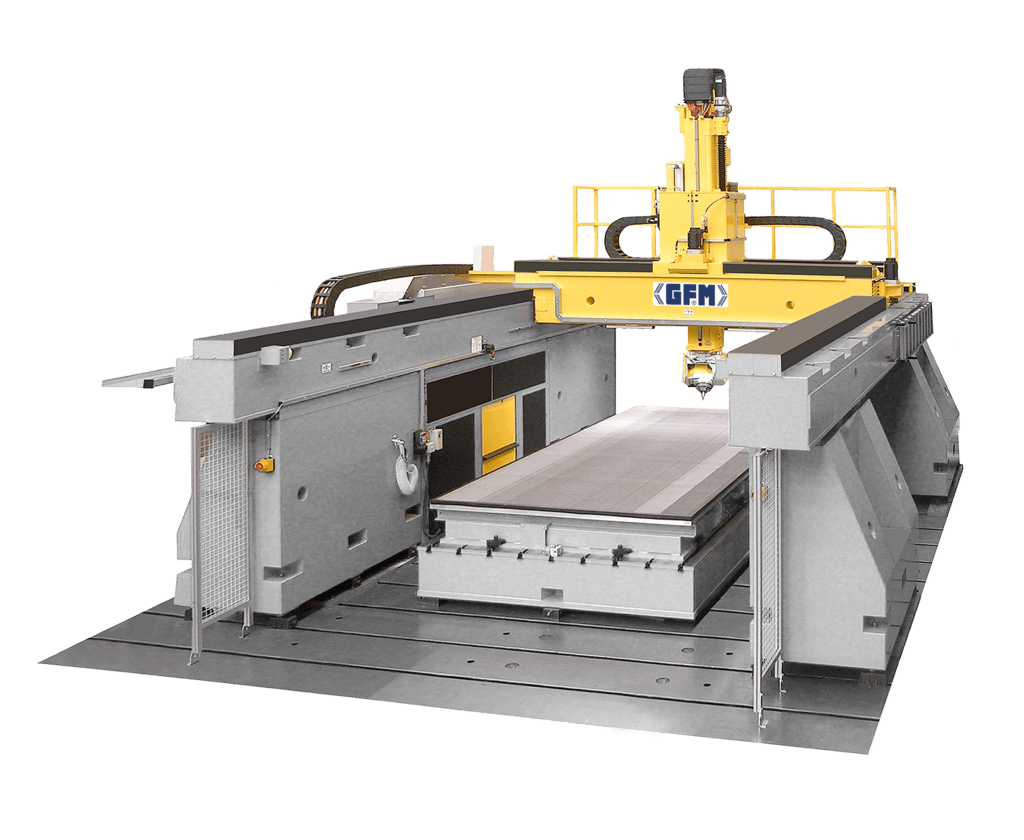

RMT-50, RMM-50, RMH-50

Large-scale 3D Cutter in 3 variants

- For light up to heavy cuts in 3D

- Highest accuracy

- Optional automatic head changer – Combination of Cutter / Router

- Wide range of configuration options

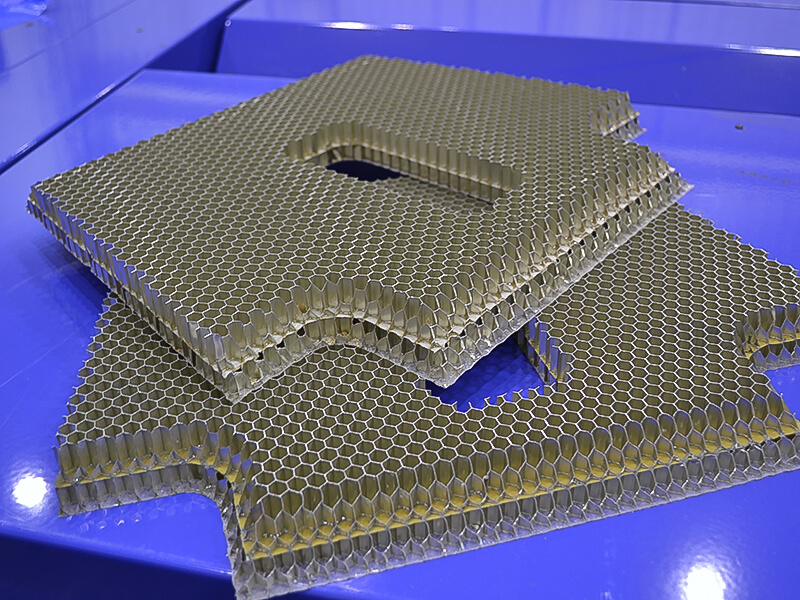

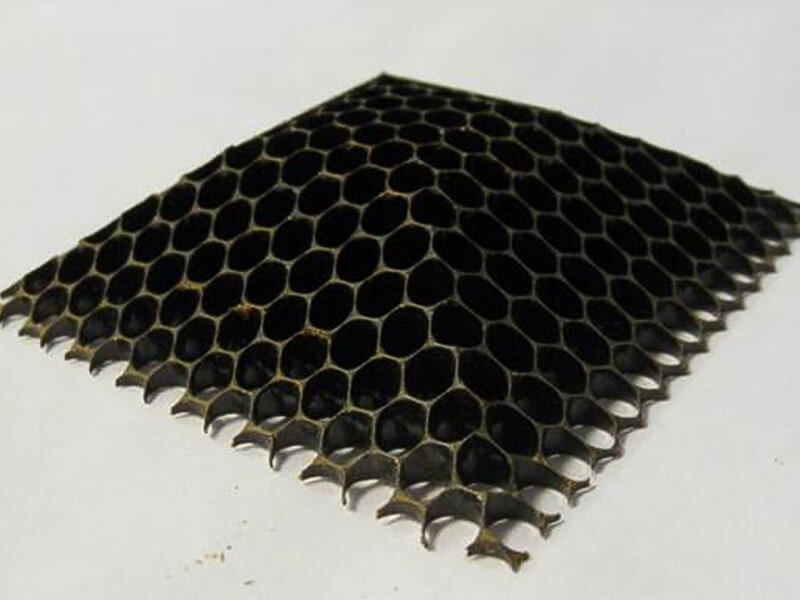

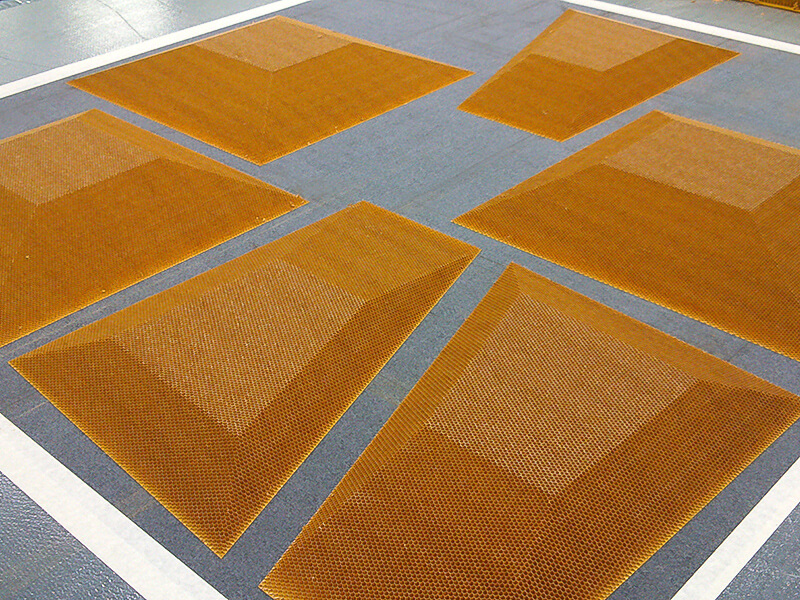

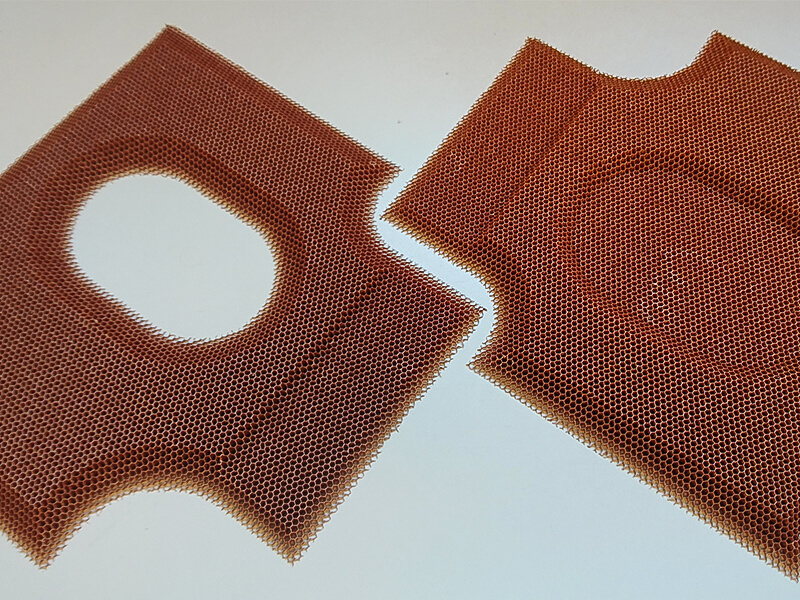

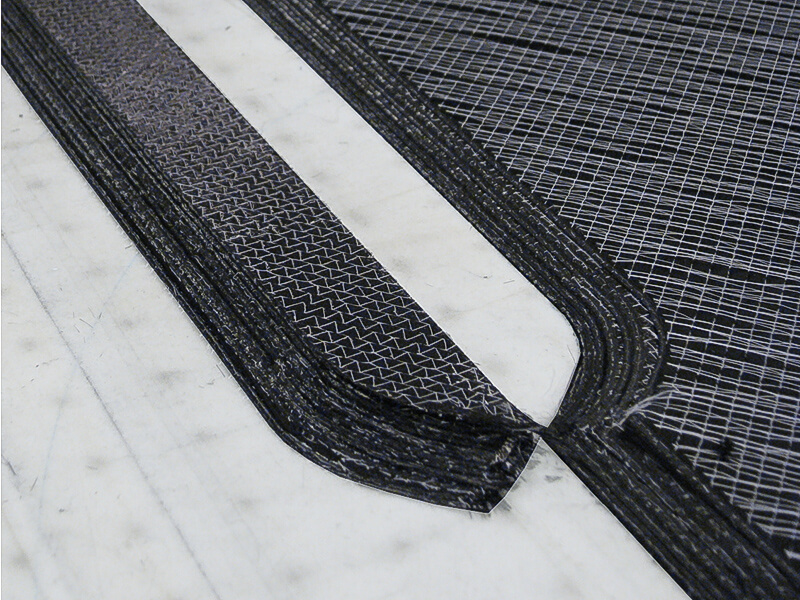

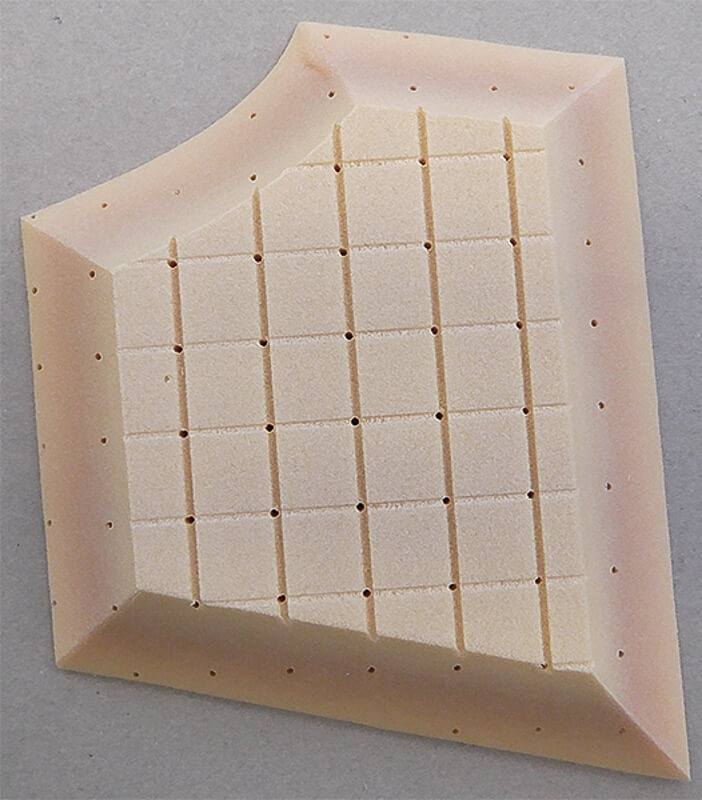

3D Cutting Samples

By far the best quality.

Highest cutting quality, lowest cutting forces, most flexible opportunities of use, material savings by nesting in honeycomb plates, contours that can be produced with a single cut of a knife. Here are some examples: