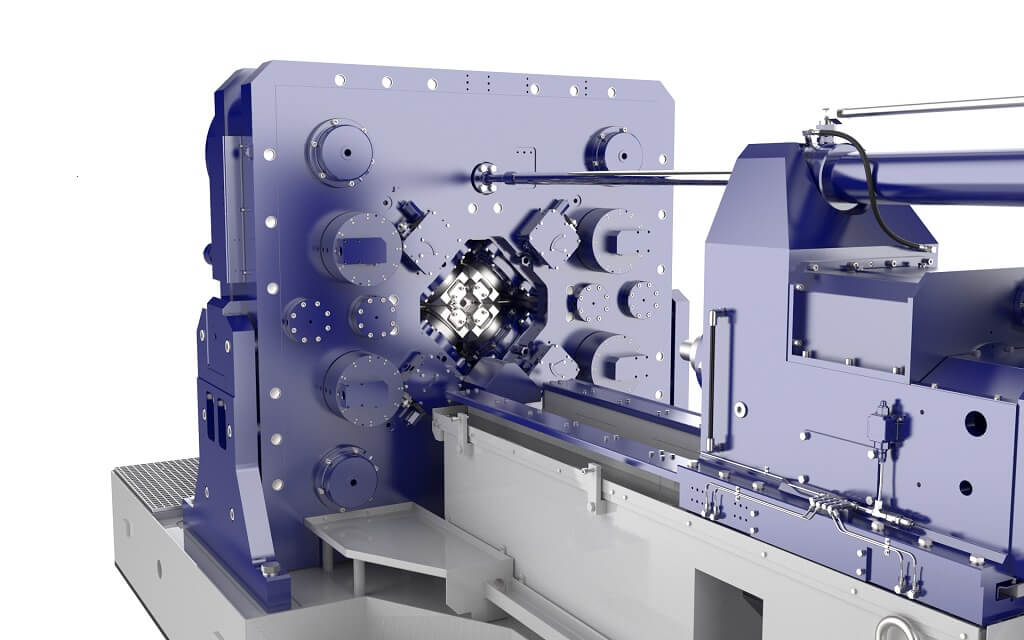

Radial Forging Machines

Radial forging technology in the automotive industry

Automotive

GFM radial forging technology is increasingly used for chip-less production of highly stressed components in the drive train, chassis, steering systems as well as in e-mobility. Weight optimisation, cost-saving potential and environmentally friendly manufacturing methods are the decisive factors here. More than 200 machines in the automotive industry impressively prove this.

Technology

Technology Radial Forging

Automotive light-weight as driver of innovation!

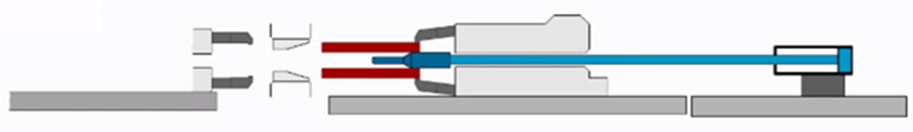

In the continuous ambition to lower further fuel consumption and CO2 emissions, automobile manufacturers are focusing on light-weight structures, higher-strength materials and e-mobility. The GFM radial forging technology, an incremental forming process with mainly 4 radially oscillating tools, offers interesting design possibilities here. The forming of metallic materials can be done in the cold, warm and hot regime. When forging with mandrels complex hollow contours can be produced in a single operation. As the material is formed and not shaped by chip-producing operations a high material utilization and improved material properties are achieved.

Your advantages

- Suitable for cold, semi-hot and hot forming

- Oil- and emission-free forming without pre-treatment of materials

- High material use due to forming instead of machining

- Inner contours can be produced with the highest accuracy

- Incremental forming with high flexibility and diverse geometries with CNC technology

- Simple tool contour (typically not limited to one size of work piece)

- Short change-over times since all relevant forming parameters are fixed in the CNC part program

ESA Machine types

A selection from our machine range.

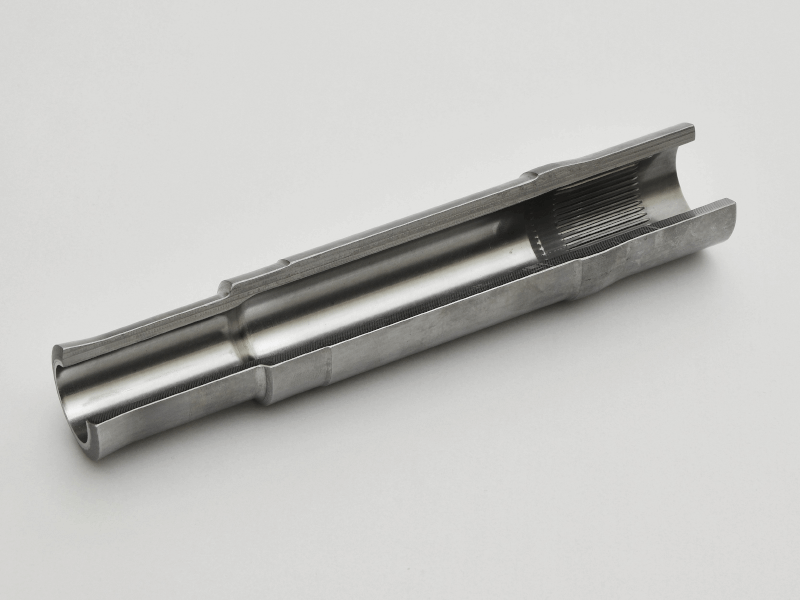

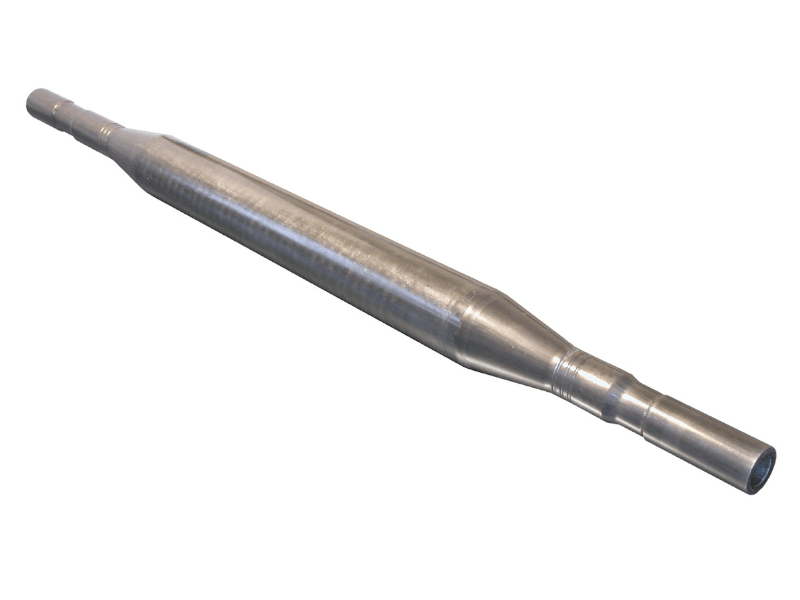

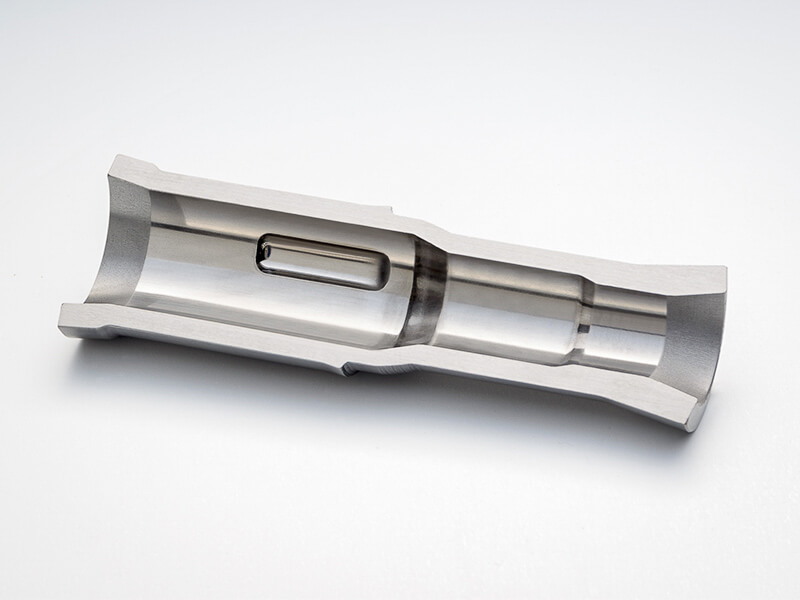

EV rotor shafts

Electrifying the future!

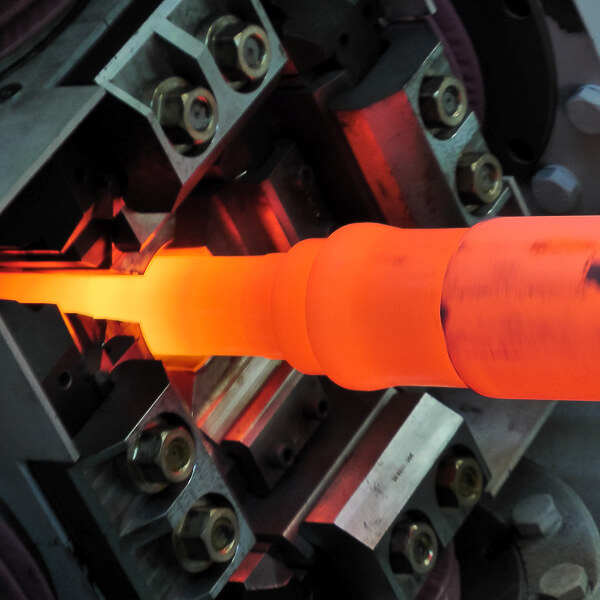

Increasing requirement for reducing local CO2 emissions and calling for regenerative energy sources, lead to spreading of electrical driving mobility. Both, Hybrid- and pure electrical cars (BEV’s) require rotor shafts for their electric power train. Due to weight- and functional issues, their geometries typically have a “hollow & bottle-shaped contour”. Machining of such inner diameters is costly, but instead will be produced quite easily by radial forging process on our machines.

Limited space requires a compact design, which causes high material- and strength specifications. Consequently, this is limiting the formability to semihot processes (approx.. 700 – 850°C) and utilizing radial forging technology.

Your advantages

- The radial forging technology favors a monobloc design (single part EV-shaft)

- A wide variety of geometries is feasible, using ordinary- and cost effective blanks

- Scope for design allows high degrees of freedom; e.g., multiple stepped ID contours, single side closed or even internal spline geometries

- Optimized wall-thickness and OD geometries with round- and even polygonal shaped forms

- Easy to manufacture forming tools -mostly not workpiece dependent- are usable, thus allows economic production, even at small lot sizes

- Short-term development- and manufacturing of prototype samples on our shop demo machines

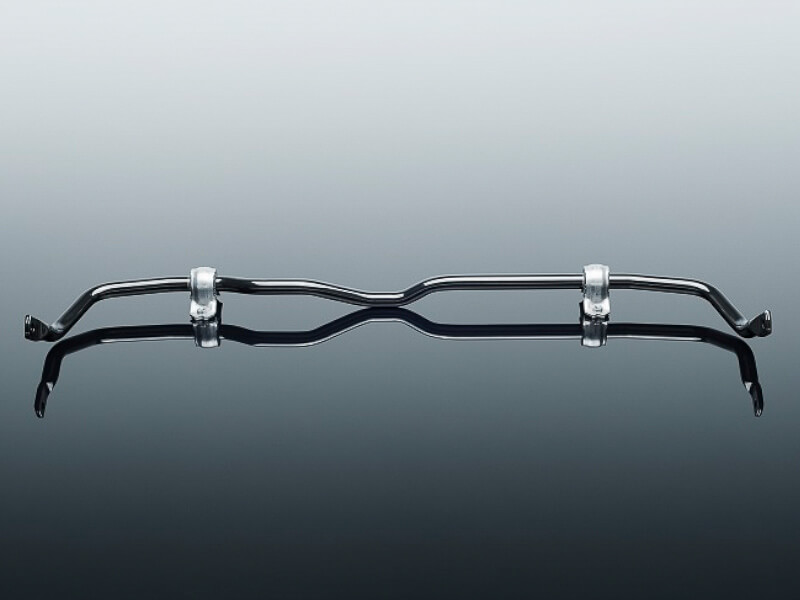

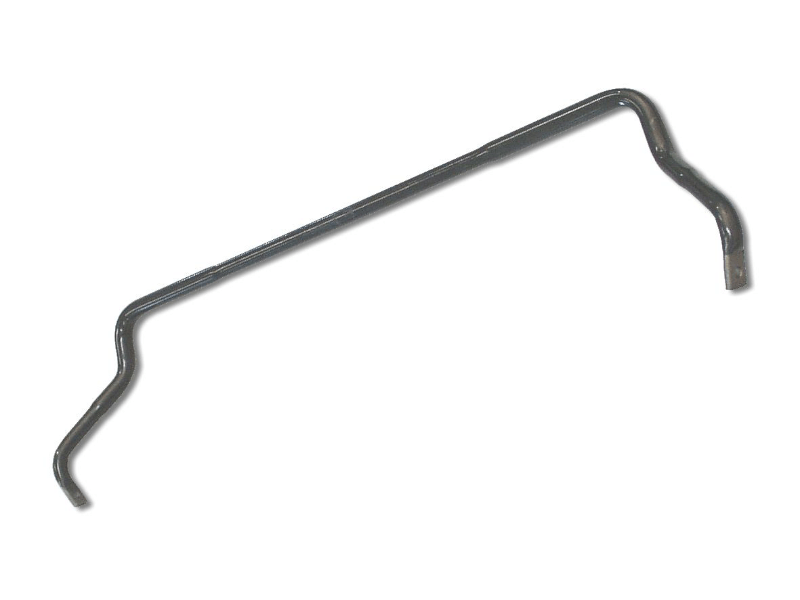

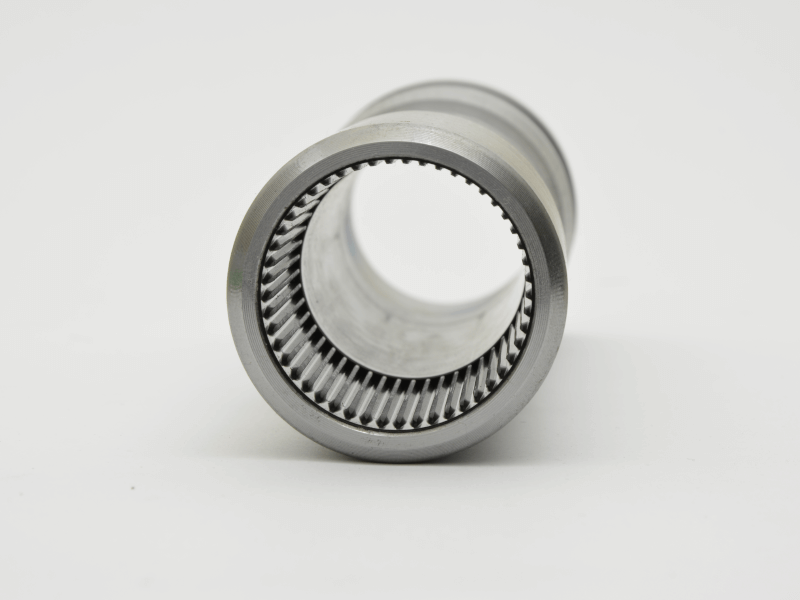

Chassis and drive train

Lower your energy and material consumption significantly!

In addition to the reduction in vehicle mass, the reduction in “undampened masses” has a very positive effect on the driving behavior of a car or light commercial vehicle. Side shafts and drive shafts are used almost exclusively in hollow construction in premium and mid-range vehicles.

Increasingly, 3-piece welded shafts are also being converted into so-called “monoblock shafts”, i.e. in one piece (so-called MTS). Significantly more than 10 million shafts per year are produced with increasing tendency by means of GFM radial forging. Hollow stabilizers with load-optimized wall thicknesses also have a large “lightweight potential” and are thus typical radial forged products.

Your advantages

- High dimension diversity with the shortest change-over times

- Best tooling life time due to partially use of cemented carbides

- No oil carry-over due to cooling with water instead of emulsion

- Excellent repeatability and therefore low QC efforts necessary

- Accurate pre-formed diameter for later-on gearing, thus no further cutting necessary

In practice:

- Stabilizer

Muhr und Bender KG, Germany, produces its stabilizers with our forging machines.

For more information on this, see Mubea.

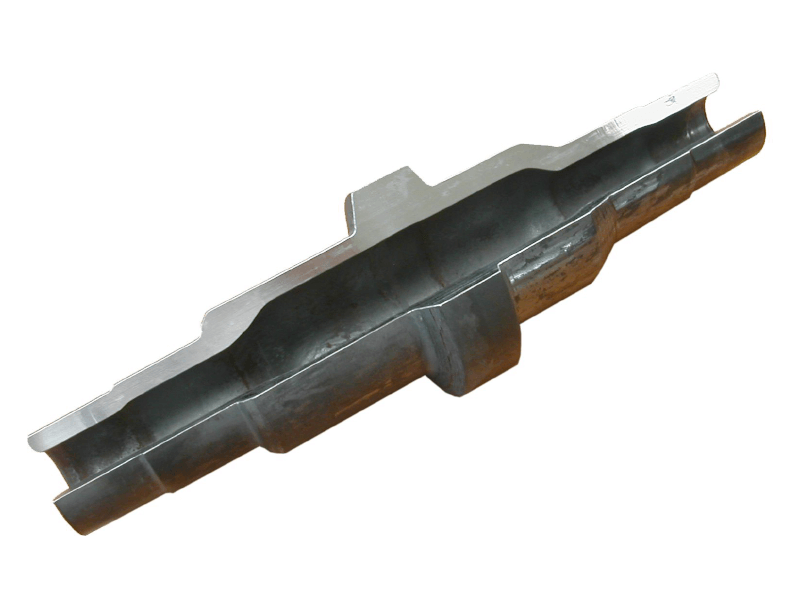

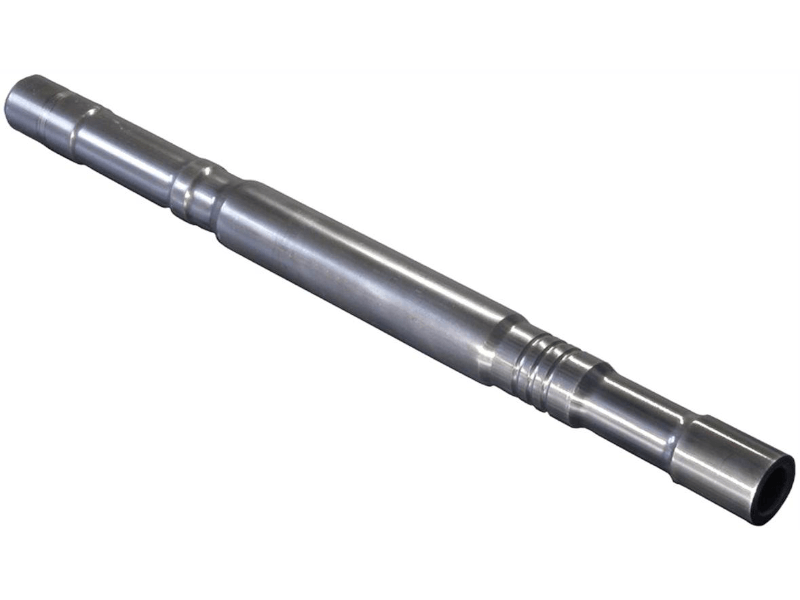

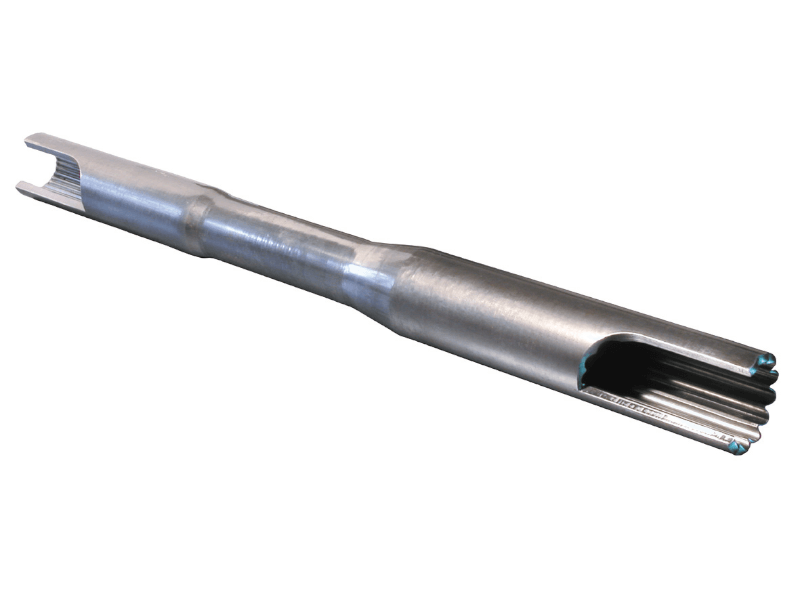

Gear Shafts

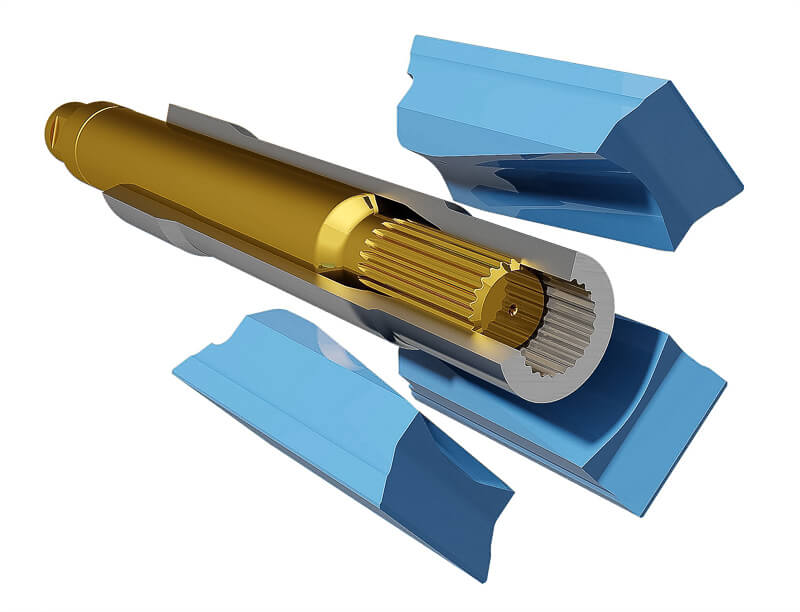

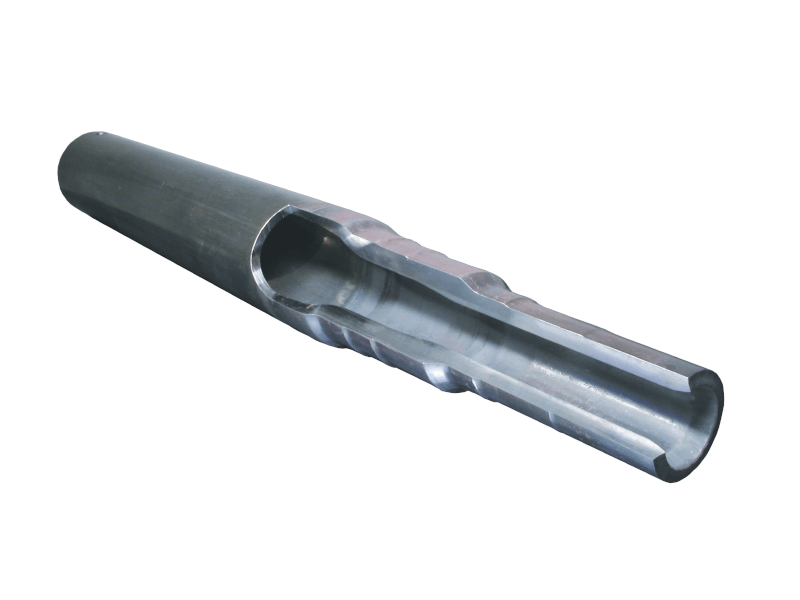

Hollow gear shafts on the rise!

The option of weight optimized design of hollow gear shafts opens a broad application range for GFM radial forging technology. Today’s gear diversity (AT, DCT, CVT, etc.), combined with increasingly high gear numbers, demands increasingly complex shaft geometries. Weight constraints demand such shafts to be hollow. Consequently, the challenges are load-optimized design with varying wall thicknesses as well as cost efficient forming of the inner contour. We meet them typically by using flow-formed blanks that we forge into near-net shape.

Your advantages

- High weight-savings potential from hollows shaft design

- Hollow shafts that are closed on one or both sides can be produced

- Implementation of the inner contour in ‘net shape’- outer contour in ‘near-net shape’

- High forming degrees can be achieved in semi-hot forming

- Distinctively higher fatigue strength

- High economic efficiency even for small lot sizes

Prototype production

We develop specifically for your needs.

We do not only sell machines, but also help you develop new forged parts. Our team of application engineers supports you from the first feasibility study to forging of trial and pre-production parts, initial production and even beyond.

What do we offer?

- Initial evaluation of a part for suitability for radial forging

- Design of your components from the blank to the finished part

- Design of the corresponding forming tools including life-time estimation

- Performance and evaluation of forging trials

- Inspection of the parts for dimensional accuracies (incl. measuring record and capability evaluation)

- Preparation of trial reports with all essential forming information

What equipment do we have?

- SKK-10 / in configuration for typical automotive applications

- SKK-10 / in long-bed design for rod and pipe forging applications

- SKK-14 / in configuration for trucks and special applications

All machines can produce hollow and solid parts in cold, semi-hot and hot conditions. We are comprehensively equipped with chamber furnaces and induction facilities for this.

Contract processing

We produce for you.

Metalltechnik Menges GmbH and GFM GmbH decide to work together!

On November 22nd, 2011, contract manufacturer Metalltechnik Menges GmbH and special machine builder GFM GmbH agreed on a technical cooperation.

Menges acquired a GFM radial forging machine of Type SKK-10 in August 2012 to produce customer parts based on contracts. 2 more forging machines of Type SKK-10/R followed in January 2016 and September 2018. All facilities are designed for cold, semi-hot and hot-forming. All facilities are designed for cold, semi-hot and hot-forming.

This way, Menges produce workpieces for customers where the required quantity does not justify a new machine, while still offering the benefits of GFM forging technology. Menges thus takes care of contract processing on GFM machines that could not be offered before.

Both companies look into the future with great confidence and are happy to offer their customers the entire range of developments and prototype production, as well as new machines.